Contract Manufacturing - Production Welding Services

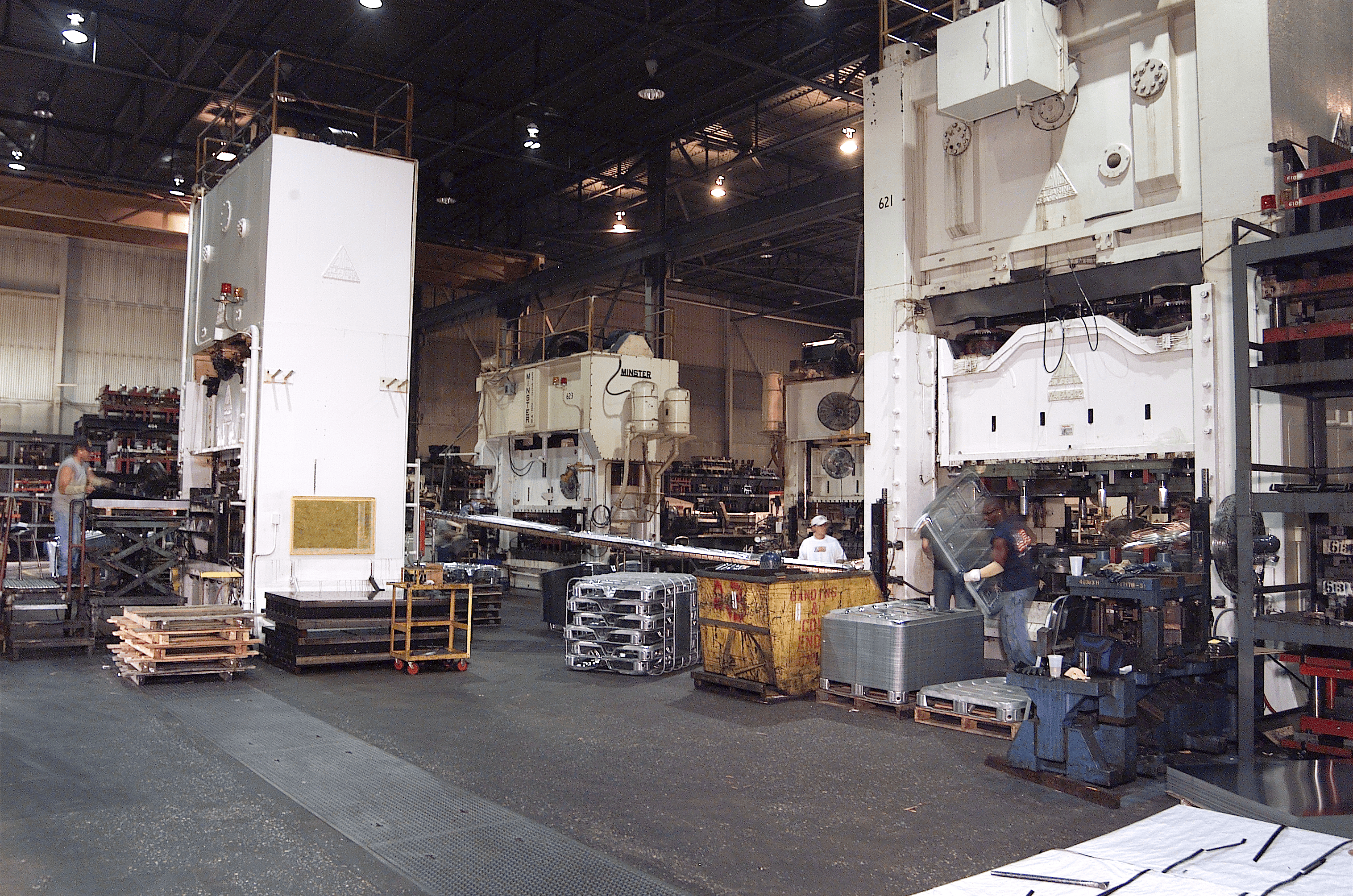

Production Welding Capabilities

- Spot welding

- Projection welding

- Cobot welding

- MIG welding

- TIG welding

- Robotic and manual welding cells

- Fronius welder for pulse welding (aluminum components)

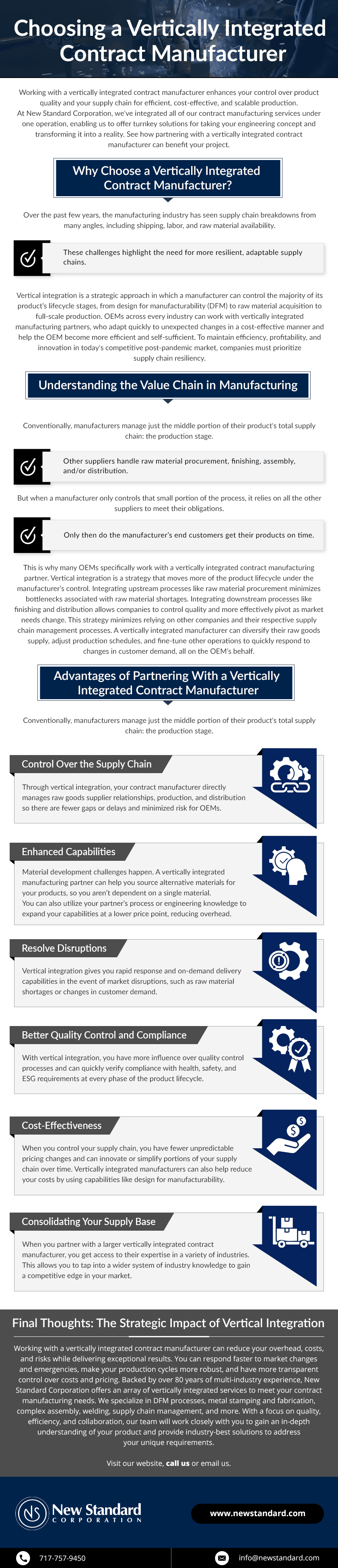

By offering specialized expertise and tailored services, we can ensure your project’s quality, precision, and compliance with regulatory standards.

Ready To Start Your Next Project?

Expertise in Complex Assemblies

New Standard is a leading provider of complex welding services for unique OEM requirements. Our team has the expertise to handle intricate designs, tight tolerances, diverse materials, and precise configuration requirements. We meet the production needs of clients across myriad industries, such as:

At New Standard, our team of engineers and technicians are well-versed in the safety, quality, and regulatory requirements of these and other industries to make sure our customers get the best products and assemblies, whether they need low-volume orders or high-volume production. Our core competencies in design for manufacturability (DFM) and turnkey contract manufacturing ensure our OEM customers get the most comprehensive solutions at market competitive pricing.

Custom Solutions and Project Flexibility

We provide full-service manufacturing services to provide turnkey solutions for every product. By working with a vertically integrated manufacturing partner like New Standard, you simplify the supply chain for all the assemblies and products in your catalog. Our comprehensive in-house services include:

- Metal stamping

- Induction brazing

- Press brake equipment

- Fiber laser cutters

- Automated heat transfer tube bundle fabrication

- Welding services, including automated and manual solutions for different metals and project types

- Value-added assembly for power generation, heat transfer, chassis assemblies, and more

- Kitting for direct-to-consumer part packaging

- Other value-added services that can be customized to your project needs

At the start of your project, NSC can support your product development process with design for manufacturability principles to ensure your new custom product is cost-effective and efficient to manufacture. DFM principles can set your projects up for success by minimizing unnecessary complications and expensive bottlenecks in the production process.

New Standard offers flexible custom solutions for any project, whether you need small specialty products or large, complex assemblies for industrial applications.

Partner With New Standard

As a leading manufacturer for OEMs, New Standard is committed to building long-term relationships with each of our clients based on trust, reliability, and comprehensive capabilities. As part of that commitment, we provide several different types of welding services, such as TIG, MIG, spot, cobot, manual, and robotic welding. In addition to these advanced welding machines, our state-of-the-art fabrication facilities house press brakes, vision systems, automated fabrication systems, and fiber lasers.

Click to Expand

Case Studies

Oil Coolers

Learn how New Standard’s vertical integration and supply chain expertise helped an OEM increase output and quality for their oil coolers.

Crossmembers

Learn how New Standard helped a customer overcome previous supply chain issues to produce high-quality steel crossmembers for their Class 8 trucks.

Fuel Dispenser Frames

New Standard provides diverse industries with optimized product solutions focused on design and cost improvement. Learn how we partnered with a long-time customer to develop new fuel dispenser frames.

Get Started With Your Contract Manufacturing Partner

Reach out to us today to learn more about our welding capabilities or to start your contract manufacturing project.