Case Study: Fuel Dispenser Frames

Fuel Dispenser Frames Overview

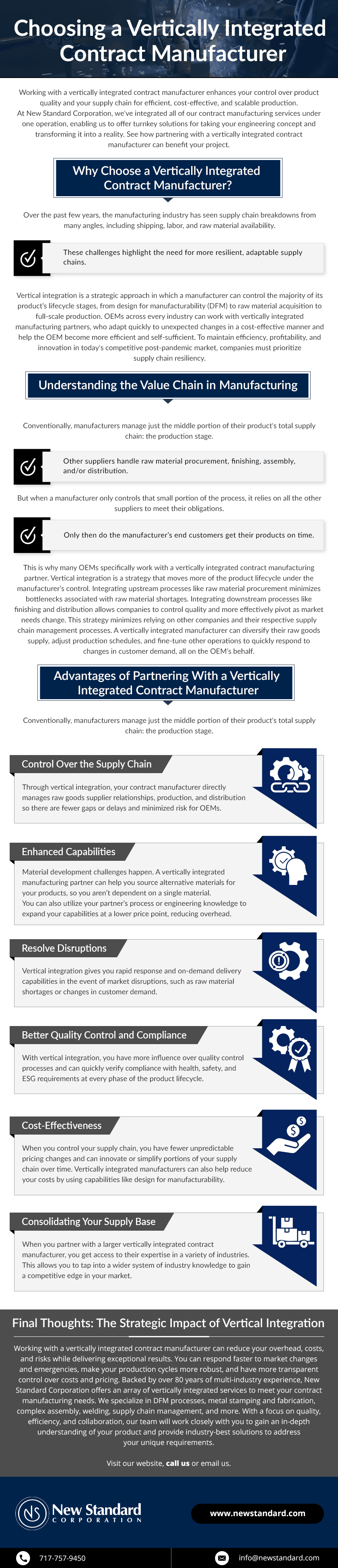

At New Standard Corporation, we specialize in providing custom, vertically integrated contract manufacturing services. Our team partners with our customers in everything from design and sourcing through to start of production. We’ll help you find efficient solutions that meet your production goals, increase profitability, and increase speed to market.

Our cross-industry expertise enables us to address challenges for OEMs in the following industries:

In the following case study, learn how we helped a client in the gas dispensing industry by leveraging our experience in design for manufacturing (DFM) processes, metal stamping and fabrication, complex assembly, and supply chain management.

Ready To Start Your Next Project?

The Challenge: Fuel Dispenser Frames

A long-time customer in the fuel dispensing industry sought help refining the design of a next-generation gas dispenser model. The client realized that the model’s size and complexity precluded the option of using traditional fabrication techniques and tooling.

Our customer needed a custom gas dispenser frame built from galvanized steel that would be 4 feet wide, 2 feet deep, and 8 feet tall. Components this large would require special tooling, as well as a significant initial investment.

Smaller metal fabrication shops do not have the ability to generate and process the unit’s parts due to their large size, nor the capacity and supplier network to produce the volumes the customer required and so they partnered with New Standard to help them find solutions.

The Solution: Turnkey Services and Financial Support

To address the tooling expense, New Standard invested over $1 million in blank tools, building this into the contract. The contract included provisions regarding decreases in product manufacturing costs for each new contract period. This would allow us to continue working with the customer for decades, utilizing our engineering expertise to reduce costs over time.

Our engineering team worked with the customer to refine their product design through our vast experience in design for manufacturability (DFM). The manufacturing process called for either a stamping or a fabrication strategy to produce the end product, and both processes had benefits for the overall delivery to market. New Standard chose an combination strategy that utilized both processes.

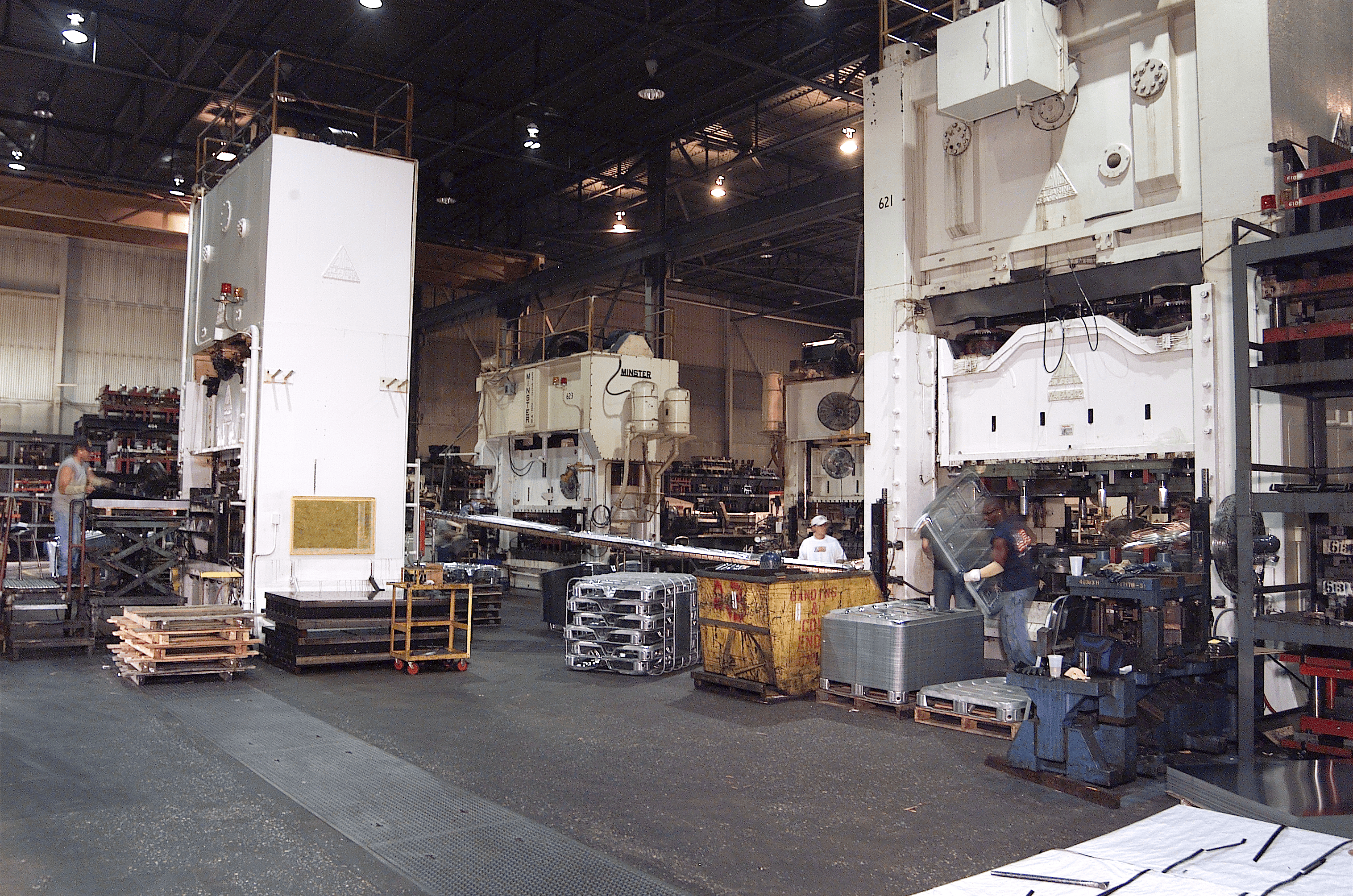

We capitalized on our core competencies of metal stamping, fabrication, and complex assembly to build the frames per the client’s specifications and volume requirements. We utilized in-house stamping presses to begin the work and press brakes for final forming. The merging of our stamping and fabrication processes enabled us to provide greater cost savings to our customer than their previous supplier had been able to achieve.

For the welding and final assembly work, we expanded the supplier network within the first nine months, entering into a joint venture with a facility near the customer to serve as a staging area for assembly. Transporting the parts required anywhere from 7 to 13 truckloads each day to keep pace with our customer’s production schedules. New Standard’s solutions allowed for flexibility in scheduling and scalable solutions for our customer’s ultimate end-users by selecting New Standard as the key coordinating partner.

At the peak of production, this assembly partner was unable to keep up with the necessary volume. NSC brought product assembly back in-house during that time to ensure timely deliveries and even after the peak had passed, continued final assembly thereby again reducing our customer’s costs.. By adapting our processes to suit the demands of the project, our vertically integrated company was able to support the client for the full lifecycle of the frame development, production, and delivery from every aspect.

The Result: Increased Savings, Improved Designs, and Lasting Partnerships

Our lead time for this product can be as low as two weeks, from start to finish. Completing the assembly nearby resulted in a dramatic decrease in shipping costs for the client while boosting our ability to provide an on-demand supply of these frames for fast receipt.

With our blended stamping and fabrication approach, the client realized a cost reduction of 30%, resulting in 7-figure annualized savings. The program earned back the initial expense for specialized tooling in less than one year, and our team was able to substantially improve upon the cost of manufacturing the frame, as contracted. In addition to reducing the cost, we also enhanced the supply chain of the product through its entire bell curve for better scalability.

Due to our company’s vertical integration, DFM approach, and process improvements, New Standard built an even stronger partnership with the client. This project has now spanned over 20 years, as we continue to find ways to refine the design and drive costs out of the product. Today, we produce up to 13 truckloads of these frames daily. As the needs of the customer change, we’ve been able to adapt with them, and we’ve since expanded our partnership to include new projects and product designs.

Custom Manufacturing Solutions to Complex Industrial Challenges With the Experts at New Standard

New Standard meets the toughest challenges head-on, with the competency and capacity to address our customer’s diverse needs. Through our commitment to DFM product development, innovation, cost reductions, and continuous improvement, we strive to add value for our customers in all aspects. To learn how New Standard can support your team through your product’s lifecycle, contact us today.

Case Studies

Oil Coolers

Learn how New Standard’s vertical integration and supply chain expertise helped an OEM increase output and quality for their oil coolers.

Crossmembers

Learn how New Standard helped a customer overcome previous supply chain issues to produce high-quality steel crossmembers for their Class 8 trucks.

Fuel Dispenser Frames

New Standard provides diverse industries with optimized product solutions focused on design and cost improvement. Learn how we partnered with a long-time customer to develop new fuel dispenser frames.