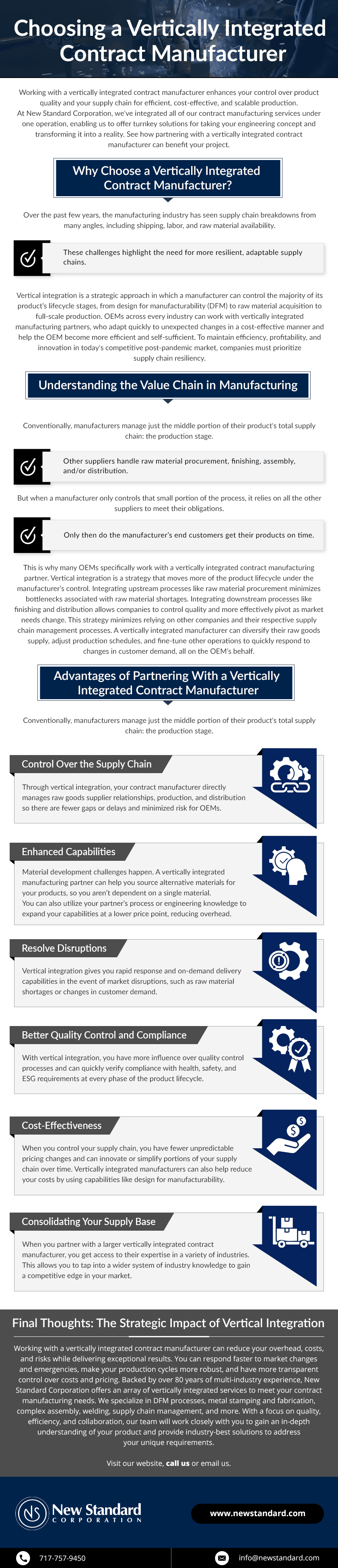

Choosing a Vertically Integrated Contract Manufacturer

Click to Expand

Working with a vertically integrated contract manufacturer enhances your control over product quality and your supply chain for efficient, cost-effective, and scalable production. At New Standard Corporation, we've integrated all of our contract manufacturing services under one operation, enabling us to offer turnkey solutions for taking your engineering concept and transforming it into a reality. See how partnering with a vertically integrated contract manufacturer can benefit your project.

Why Choose a Vertically Integrated Contract Manufacturer?

Over the past few years, the manufacturing industry has seen supply chain breakdowns from many angles, including shipping, labor, and raw material availability. These challenges highlight the need for more resilient, adaptable supply chains. Vertical integration is a strategic approach in which a manufacturer can control the majority of its products’ lifecycle stages, from design for manufacturability (DFM) to raw material acquisition to full-scale production. OEMs across every industry can work with vertically integrated manufacturing partners, who adapt quickly to unexpected changes in a cost-effective manner and help the OEM become more efficient and self-sufficient. To maintain efficiency, profitability, and innovation in today's competitive post-pandemic market, companies must prioritize supply chain resiliency.

Understanding the Value Chain in Manufacturing

Conventionally, manufacturers manage just the middle portion of their product's total supply chain: the production stage. Other suppliers handle raw material procurement, finishing, assembly, and/or distribution. But when a manufacturer only controls that small snippet of the process, it relies on all the other suppliers to meet their obligations. Only then do the manufacturer’s end customers get their products on time.

This is why many OEMs opt to work with a vertically integrated contract manufacturing partner. Vertical integration is a strategy that puts more of the product lifecycle under the manufacturer’s control. Integrating upstream processes like raw material procurement minimizes bottlenecks associated with raw material shortages, and integrating downstream processes like finishing and distribution allows companies to control quality and more effectively pivot as market needs change.

This strategy minimizes reliance on other companies and their respective supply chain management processes. A vertically integrated manufacturer can diversify their raw goods supply, adjust production schedules, and fine-tune other operations to quickly respond to changes in customer demand, all on the OEM’s behalf.

Advantages of Partnering With a Vertically Integrated Contract Manufacturer

Vertically integrated manufacturers can benefit your OEM business in the following ways:

- Control Over the Supply Chain: Through vertical integration, your contract manufacturer directly manages raw goods supplier relationships, production, and distribution so there are fewer gaps or delays and minimized risk for OEMs.

- Enhanced Capabilities: Material development challenges happen. A vertically integrated manufacturing partner can help you source alternative materials for your products so you aren’t dependent on a single material. You can also utilize your partner’s process or engineering knowledge to expand your capabilities at a lower cost, reducing overhead.

- Resolve Disruptions: Vertical integration gives you rapid response and on-demand delivery capabilities in the event of market disruptions, such as raw material shortages or changes in customer demand.

- Better Quality Control and Compliance: With vertical integration, you have more control over quality control processes and can quickly verify compliance with health, safety, and ESG requirements at every phase of the product lifecycle.

- Cost-Effectiveness: When you control your supply chain, you have fewer unpredictable pricing changes and can innovate or simplify portions of your supply chain over time. Vertically integrated manufacturers can also help reduce your costs by using capabilities like design for manufacturability.

- Consolidating Your Supply Base: When you partner with a larger vertically integrated contract manufacturer, you get access to their expertise in a variety of industries. This allows you to tap into a wider system of industry knowledge to gain a competitive edge in your market.

Case Studies

Fuel Dispenser Frames

New Standard provides diverse industries with optimized product solutions focused on design and cost improvement. Learn how we partnered with a long-time customer to develop new fuel dispenser frames.

Final Thoughts: The Strategic Impact of Vertical Integration

Working with a vertically integrated contract manufacturer can reduce your overhead, costs, and risks while delivering exceptional results. You can respond faster to market changes and emergencies, make your production cycles more robust, and have more transparent control over costs and pricing.

Backed by over 80 years of multi-industry experience, New Standard Corporation offers an array of vertically integrated services to meet your contract manufacturing needs. We specialize in DFM processes, metal stamping and fabrication, complex assembly, welding, supply chain management, and more. With a focus on quality, efficiency, and collaboration, our team will work closely with you to gain an in-depth understanding of your product and provide industry-best solutions to address your unique requirements.

Contact New Standard to learn how our vertical integration strategies can benefit your business.

Related Posts

Nothing found.